Parging is a crucial technique in masonry and construction that involves applying a thin layer of cement-based coating to walls, typically foundation walls or other masonry surfaces. This process serves multiple purposes, primarily focusing on protecting and waterproofing the underlying structure. The parging mixture usually consists of cement, sand, and water, sometimes with additional additives for enhanced performance.

The parging process begins with preparing the surface by cleaning and dampening it. Then, the cement mixture is applied in thin, even layers using a trowel or specialized parging tools. Multiple coats may be necessary to achieve the desired thickness and coverage. As the coating dries, it forms a protective barrier against moisture infiltration and helps to conceal minor imperfections in the masonry work.

One of the primary benefits of parging is its role in foundation waterproofing. By creating a smooth, water-resistant surface, it helps prevent water from seeping into the foundation, which can lead to structural damage over time. Additionally, parging can improve the aesthetic appearance of rough or uneven masonry surfaces, providing a clean, uniform look to the exterior of a building.

While parging is an effective method for masonry protection, it’s important to note that it requires periodic maintenance and may need to be reapplied every few years to ensure continued effectiveness. When done correctly, parging can significantly extend the lifespan of masonry structures and enhance their overall durability.

The History and Evolution of Parging Techniques

Parging, a technique used to protect and enhance masonry surfaces, has a rich history dating back centuries. Traditional parging methods involved applying a mixture of lime, sand, and water to exterior walls, providing a protective layer against the elements. This practice was widely used in ancient civilizations, including Rome and Egypt, to preserve their impressive stone structures.

As time progressed, the composition of parging mixtures evolved. In the 19th century, the introduction of Portland cement revolutionized the construction industry, including parging techniques. This new material offered improved durability and water resistance, leading to its widespread adoption in masonry protection.

Modern parging techniques have further refined the process, incorporating advanced materials such as polymer-modified mortars and acrylic-based compounds. These innovations have significantly enhanced the longevity and effectiveness of parging applications, offering superior adhesion and flexibility.

The evolution of masonry protection has also seen the development of specialized tools and application methods. From traditional hand-troweling to modern spray-on techniques, the industry has continuously adapted to improve efficiency and consistency in parging applications.

Today, parging continues to play a crucial role in preserving both historical structures and contemporary buildings, demonstrating the enduring importance of this ancient craft in modern construction practices.

Materials Used in Parging: From Cement to Polymers

When it comes to parging, the choice of materials plays a crucial role in the durability and effectiveness of the finish. Traditional cement-based parging mixes have long been the go-to option for many builders and homeowners. These mixes typically consist of Portland cement, sand, and water, offering a cost-effective and reliable solution for covering foundation walls and masonry surfaces.

However, advancements in construction technology have introduced new materials to the parging landscape. Polymer-modified parging mixes have gained popularity due to their enhanced flexibility and adhesion properties. These mixes incorporate polymers into the traditional cement blend, resulting in a more resilient finish that can better withstand temperature fluctuations and minor structural movements.

Acrylic parging is another innovative option that has emerged in recent years. This material offers excellent water resistance and can be applied in thinner coats compared to traditional cement-based mixes. Acrylic parging is particularly suitable for areas prone to moisture issues or where a smoother finish is desired.

The selection of parging material depends on various factors, including climate conditions, substrate type, and desired aesthetic. While cement-based mixes remain popular for their affordability and familiarity, polymer-modified and acrylic options are gaining traction for their enhanced performance characteristics. Ultimately, the choice of material should be based on the specific requirements of each project, ensuring a durable and effective parging application.

The Step-by-Step Process of Applying Parge Coat

The process of applying a parge coat involves several crucial steps to ensure a durable and attractive finish. Begin with thorough surface preparation, which includes cleaning the wall and repairing any cracks or damages. Next, mix the parging material according to the manufacturer’s instructions, achieving a consistency similar to thick pancake batter.

Application techniques vary, but generally involve using a hawk and trowel to apply the mixture in thin, even layers. Start from the bottom and work your way up, using smooth, sweeping motions to create a uniform texture. Depending on the desired finish, you may need to apply multiple coats.

The curing process is essential for the longevity of the parge coat. Keep the surface moist for at least 48 hours after application, using a fine mist sprayer if necessary. This allows the mixture to set properly and prevents cracking.

Essential parging tools include a mixing bucket, hawk, trowel, and finishing brush. Some professionals also use specialized tools like a darby or float for achieving specific textures. With proper technique and the right tools, applying a parge coat can significantly improve the appearance and durability of masonry surfaces.

Benefits of Parging for Home and Building Maintenance

Parging offers numerous advantages for both residential and commercial structures. Primarily, it serves as an excellent moisture barrier, protecting walls from water infiltration and potential damage. This protective layer not only safeguards against moisture-related issues but also enhances the aesthetic appeal of buildings, providing a smooth, uniform surface that can be painted or left as-is for a clean, modern look.

Beyond its protective and visual benefits, parging contributes to improved insulation. The additional layer helps to reduce heat transfer through walls, potentially leading to increased energy efficiency and lower utility costs. This insulating effect is particularly beneficial in older buildings with less efficient thermal properties.

Structurally, parging can reinforce walls, especially in older buildings with deteriorating mortar joints. By filling in small cracks and imperfections, it helps to stabilize the surface and prevent further degradation. This reinforcement can extend the lifespan of the building’s exterior and reduce the need for more extensive repairs in the future.

Overall, the combination of moisture protection, aesthetic improvement, insulation benefits, and structural reinforcement makes parging a valuable technique for maintaining and enhancing both homes and commercial buildings. Its ability to address multiple aspects of building maintenance simultaneously makes it a cost-effective solution for property owners looking to improve their structures’ longevity and efficiency.

Common Problems and Troubleshooting in Parging

Parging, while an effective method for protecting and enhancing walls, can encounter several issues over time. Understanding these problems and their solutions is crucial for maintaining the integrity of your parged surfaces.

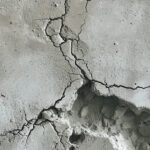

Cracking is one of the most frequent issues in parging. These cracks can occur due to settling, temperature fluctuations, or improper application. Small cracks can often be filled with a matching mortar mix, while larger cracks may require removing and reapplying the affected area.

Peeling parge coat is another common problem, typically caused by poor surface preparation or moisture issues. To address this, remove the loose material, clean the surface thoroughly, and reapply the parge coat, ensuring proper bonding.

Efflorescence, the white, powdery substance that sometimes appears on parged surfaces, is caused by water-soluble salts migrating to the surface. While primarily an aesthetic issue, it can indicate underlying moisture problems. Cleaning with a mild acid solution and addressing the moisture source can help prevent recurrence.

Freeze-thaw damage is particularly problematic in colder climates. This occurs when water penetrates the parge coat, freezes, expands, and causes the coating to crack or spall. Using a more flexible parging mix and ensuring proper drainage can mitigate this issue.

Various repair techniques can be employed depending on the severity of the damage. For minor issues, patching with a matching mortar mix may suffice. More extensive damage might require removing the affected area and reapplying a new parge coat, potentially with the addition of a bonding agent for better adhesion.

Regular inspection and maintenance can help identify and address these issues early, prolonging the life and effectiveness of your parging.

DIY Parging vs. Professional Services: What to Consider

When considering parging your home’s foundation, you’ll need to decide between a DIY approach and hiring professional services. Each option has its merits, and your choice will depend on several factors.

Cost comparison is often the first consideration for homeowners. DIY parging can be significantly cheaper, as you’ll only need to purchase materials. However, professional services, while more expensive, may offer better long-term value due to superior workmanship.

Skill requirements are crucial when contemplating a DIY project. Parging requires a certain level of expertise to achieve a smooth, durable finish. If you’re handy and willing to learn, DIY might be feasible. Otherwise, professionals bring years of experience to the task.

Time investment is another important factor. DIY parging can be time-consuming, especially for beginners. Professionals can complete the job more quickly, minimizing disruption to your daily life.

Quality assurance is a significant advantage of hiring professionals. They have the knowledge to properly prepare surfaces, mix materials, and apply the parging for optimal durability and appearance.

Consider hiring professionals when the job is extensive, involves hard-to-reach areas, or requires repairing significant damage. Their expertise can prevent costly mistakes and ensure a long-lasting result.

Ultimately, your decision should balance your budget, skills, available time, and desired outcome to determine the best approach for your parging project.

Parging Alternatives and Complementary Techniques

When considering alternatives to parging, several effective options can protect and enhance your foundation’s appearance. Stucco application offers a durable and aesthetically pleasing finish, providing excellent weather resistance and customizable textures. Concrete resurfacing is another viable option, ideal for repairing and smoothing damaged surfaces while adding a fresh look to your foundation.

Masonry sealing presents a less invasive alternative, creating a protective barrier against moisture and environmental factors without altering the original appearance of the foundation. For those seeking comprehensive protection, foundation wraps offer a modern solution, effectively waterproofing and insulating the entire foundation perimeter.

A comparative analysis of these techniques reveals that each has its strengths:

- Stucco excels in durability and aesthetic versatility.

- Concrete resurfacing is best for repairing extensive damage.

- Masonry sealing is ideal for preserving original appearances.

- Foundation wraps provide superior moisture protection and insulation.

Ultimately, the choice depends on your specific needs, budget, and desired outcome. Consider consulting with a professional to determine the most suitable option for your foundation’s unique requirements.

Maintenance and Care for Parged Surfaces

Maintaining parged surfaces is essential for preserving their appearance and structural integrity. Regular cleaning of parged walls helps prevent the buildup of dirt, mold, and other contaminants that can compromise the surface. Use a soft brush or low-pressure water spray to gently remove debris, avoiding harsh chemicals that may damage the parging.

Periodic inspections are crucial for identifying potential issues early on. Check for cracks, chips, or areas where the parging may be separating from the underlying surface. These inspections should be conducted at least twice a year, ideally in spring and fall.

When minor damage is detected, prompt touch-up techniques can prevent further deterioration. Small cracks can be filled with a matching parging mix, while larger areas may require professional repair. Always ensure the surface is clean and slightly dampened before applying any touch-up material.

For long-term preservation, consider applying a breathable sealer to protect the parged surface from moisture infiltration. This is particularly important in regions with freeze-thaw cycles, as water expansion can cause significant damage over time.

Seasonal care is also vital for maintaining parged surfaces. In winter, avoid using de-icing salts near parged walls, as they can cause deterioration. During summer, protect the surface from excessive heat and direct sunlight, which can lead to cracking. By following these maintenance practices, you can significantly extend the life and appearance of your parged surfaces.

The Future of Parging in Construction and Renovation

As we look to the future of construction and renovation, parging continues to play a vital role in protecting and enhancing structures. This versatile technique offers both functional and aesthetic benefits that are likely to remain relevant for years to come. Advancements in materials science may lead to the development of more durable and environmentally friendly parging mixtures, potentially extending the lifespan of applications and reducing maintenance requirements.

The growing emphasis on sustainable building practices may also influence parging techniques, with a focus on using recycled materials or those with a lower carbon footprint. Additionally, as climate change impacts become more pronounced, parging’s ability to protect against moisture and temperature fluctuations may become increasingly valuable.

In the realm of historic preservation, parging will continue to be an essential tool for restoring and maintaining older structures, helping to bridge the gap between traditional craftsmanship and modern building standards. As the construction industry evolves, parging is likely to adapt and integrate with new technologies and methods, ensuring its place in both residential and commercial projects for the foreseeable future.